Application of molybdenum bolts in high temperature vacuum furnace

High temperature vacuum furnace is an important equipment used in various high temperature experiments and material handling processes. In high temperature environments, various elements and materials will interact and react, so the equipment used in high temperature vacuum furnaces must have high temperature resistance, corrosion resistance and sealing performance. Among them, molybdenum bolt plays a key role as one of the important components of high temperature vacuum furnace.

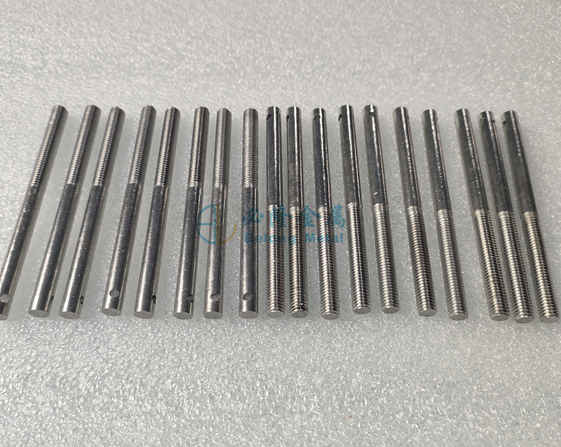

Molybdenum bolt is a threaded connection made of molybdenum material, which has good high temperature resistance and corrosion resistance. Because the melting point of molybdenum is as high as 2620 degrees Celsius, and molybdenum is not easy to react with most substances at high temperatures, molybdenum bolts can withstand extremely harsh working conditions in high temperature vacuum furnaces.

First, molybdenum bolts are used to fix and connect various components and accessories in high temperature vacuum furnaces. Components such as heating elements, insulation layers and reflectors in high temperature vacuum furnaces need to be firmly connected by molybdenum bolts. Due to the particularity of the high temperature environment inside the high temperature vacuum furnace, the general bolts are difficult to withstand long-term high temperature and corrosion, and molybdenum bolts can work stably in a high temperature environment to ensure the safe and reliable operation of the equipment.

Secondly, molybdenum bolts are also used in sealing devices in high temperature vacuum furnaces. In order to ensure the stability and sealing of the internal vacuum environment during the operation of the high-temperature vacuum furnace, it is usually necessary to use a sealing ring between the furnace body and the accessories, and to fix it tightly through molybdenum bolts. The high temperature and corrosion resistance of molybdenum bolts ensure the reliability of the sealing device and prevent gas leakage in the vacuum furnace and the infiltration of external gases.

Finally, molybdenum bolts can also be used to adjust and control the position and Angle of heating elements in high temperature vacuum furnaces. The heating element is one of the core components in the high temperature vacuum furnace. The precise positioning and Angle control of the heating element can be realized through the loose adjustment of the molybdenum bolt, so as to ensure the uniform heating of the sample and the accuracy of the high temperature experiment.

In short, molybdenum bolts play a vital role in high temperature vacuum furnaces. Its high temperature resistance, corrosion resistance and reliable connection performance ensure the stable operation of the high temperature vacuum furnace and the accuracy of the experimental data. With the development of high temperature technology and the continuous expansion of application, the application prospect of molybdenum bolt in high temperature vacuum furnace will be more broad. At the same time, it is also necessary to continuously improve and develop new types of molybdenum bolts to meet higher temperature requirements and more complex working environments.

Frank Guo

Frank Guo

+86 13026443801

+86 13026443801

+86 0917-3228322

+86 0917-3228322

+86 0917-3228322

+86 0917-3228322

sales@belongmetal.com

sales@belongmetal.com

Guojiacun Industrial zone, Maying Town, Weibin Zone, Baoji, Shaanxi 721000, P.R.China

Guojiacun Industrial zone, Maying Town, Weibin Zone, Baoji, Shaanxi 721000, P.R.China